Did you know that according to a study by the Department of Energy 28% of large power transformer failures are due to electrical disturbances, not including lightning? While many of these disturbances can cause the failure, age is an important factor as the conductor insulation weakens over time which prohibits the transformers ability to sustain mechanical stress. You can read the entire study here.

The A-Line teams were busy this June, traveling the coast. Three of these projects included services to assist with the root cause failure of a large power transformer. While each scenario and the degree of evaluation varies, we take special care in the detailed dissection of these transformers to allow a thorough collection of evidence including photos, paper samples and any required testing. Our goal is to help our customers learn as much as possible in order to better the maintenance of their transformer fleet.

This first project brought us to the east coast to evaluate a transformer for a customer that has many like units within their system. The total in-service weight of this transformer is over 900,000 pounds.

A-Line disassembled all of external components in preparation for the tank removal. These components, including the tap changer, were dissected and examined. Once the tank was off, the core was made available for an initial inspection.

The team removed the top yoke of the transformer and then utilized our specialized equipment for the careful segregation of the transformer windings. This separation allows for detailed inspection of all phases including photos and sampling when required.

This transformer’s massive core legs were then carefully removed and loaded out for further recycling. Once all inspection was complete the crew removed all remaining materials and shipped for additional recycling.

Meanwhile, another crew was working diligently on the southern coast, providing forensic services on a large shell type transformer weighing in at just over 700,000 pounds.

After removing the radiators, bushings and conservator tank, the crew prepped the transformer by cutting the lower tank section. The upper transformer tank section was then lifted to expose the core for initial inspection- which included an immediate area indicating failure. The A-Line team worked with plant engineering and outside consultants to evaluate the failure source.

Once the core steel was removed the winding damage became apparent. Insulation failure due to probable moisture in the oil was a factor for this transformer. The area was photographed and sampled. Once this inspection was complete the windings were removed and shipped for further recycling.

The A-Line team was able to remove this transformer and provide the forensic services needed in a total of 4 days- minimizing additional expense in having personnel on site for an extended period of time.

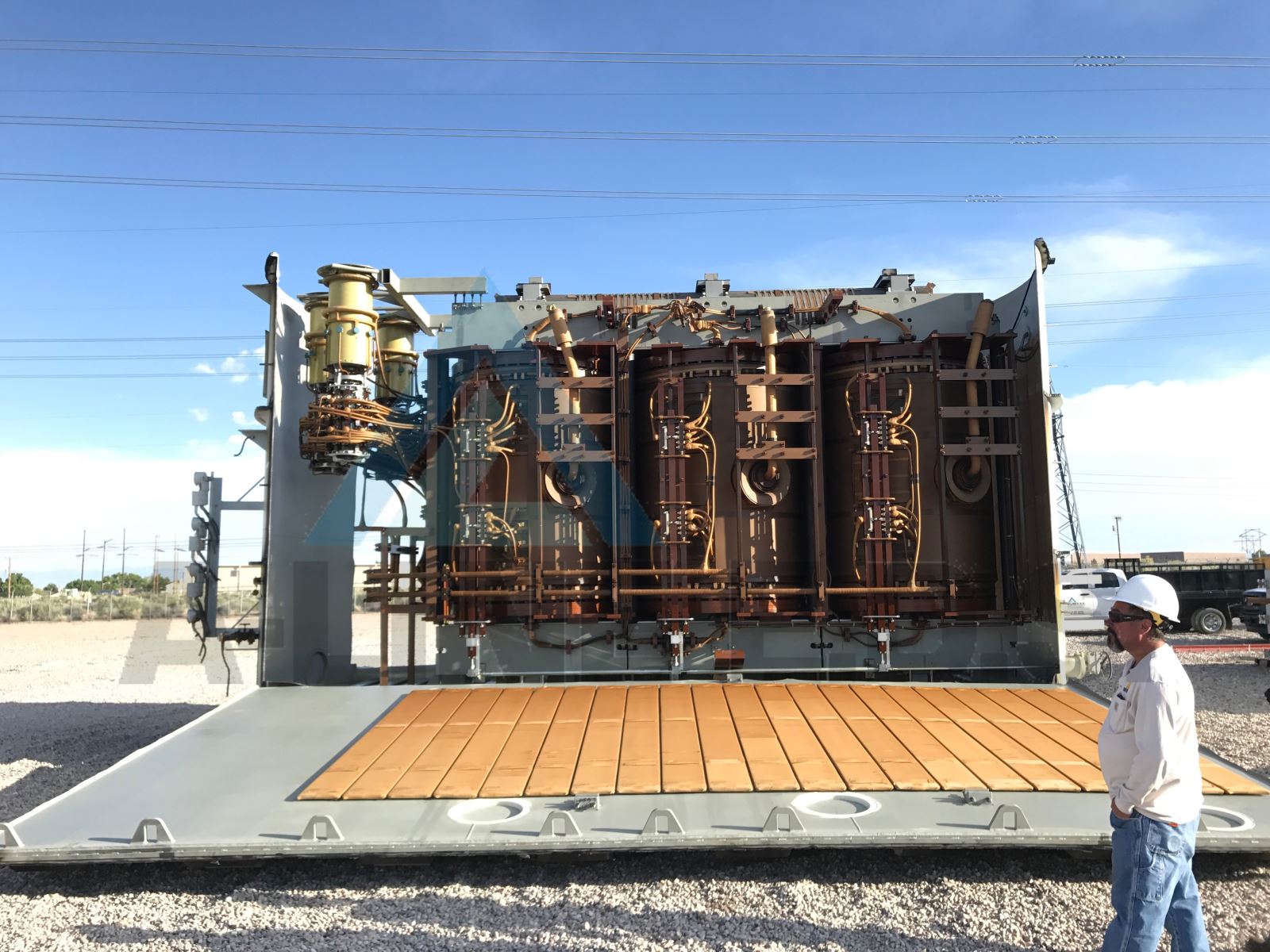

Finally, we rounded out the month of June with this large power transformer failure in the west. This large core style transformer weighed over 700,000 lbs. A-Line was contracted to provide a detailed forensic investigation for this customer.

The transformer was carefully opened to expose the core and coil for an initial inspection.

Once the top yoke was removed the windings were carefully segregated utilizing a system designed by A-Line to provide a factory style teardown in the field. Once segregated it was confirmed that the windings had buckled which ultimately led to the transformer failure.

After all photos were taken and the necessary investigative measures were followed, A-Line continued with the careful removal and load out of the transformer core steel. These large core legs require full attention to safety as the material is very sharp and heavy. A-Line’s teams have extensive training and specialized tooling which allows the team to safely and efficiently remove the core steel. Once materials are removed our team cleans the site of any remaining debris- leaving it cleaner than when we arrived.

Whether it is an electrical disturbance, design flaw or other failure mode A-Line strives to provide the best large power transformer forensic services in the country. We design our service to fit unique needs. If we can’t do it, it can’t be done.